How to Install Small Workstation Bridge Crane

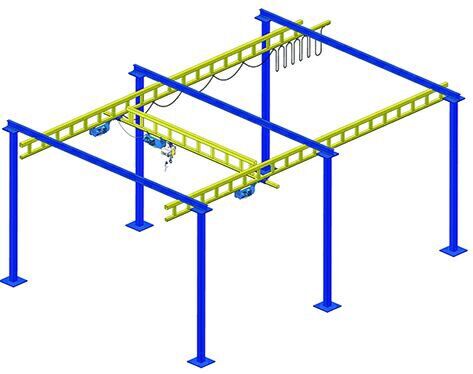

In modern workshops and production lines, small workstation bridge crane has become common equipment for improving production efficiency and reducing labor intensity due to their compact structure, flexible installation and convenient use. KFCS systematically analyzes the entire installation process for you to help you achieve safe, compliant, accurate and efficient equipment deployment.

Preparation before installation

Site survey and measurement

● Confirm the workshop clearance height, support beam specifications and load-bearing capacity;

● Measure the span of the main beam, the installation position of the track and the fixing points at both ends;

● Check the layout of the ground and auxiliary equipment (such as power supply, lighting) to ensure that the installation space is unobstructed.

Equipment and tool inventory

● Girder, end beam, trolley, lifting mechanism (electric hoist or chain hoist), rail or guide rail, fasteners and electrical box;

● Lifting tools (rigging, jack, lifting chain), wrench, bolt tightening kit, electric drill, level, safety rope and other tools;

● Protective equipment (safety helmet, safety belt, gloves, goggles).

Construction team and plan confirmation

● Organize professionals such as lifting, welding, electrical, and assembly, and clarify the division of labor;

● Develop detailed installation plans and schedules based on equipment drawings and site conditions;

● Do a good job of construction safety briefing to ensure that all personnel understand the key points of operation and emergency plans.

Installation steps

Support beam and track installation

● Install special lifting lugs or U-shaped hanging plates on the main beam of the workshop or the reserved support frame to ensure that the position is vertical and the spacing is accurate;

● Fix the guide rail or rail on the lifting lug, and use a level to correct the horizontality. The longitudinal and lateral errors of the track shall not exceed 2 mm;

● Use pre-tightening bolts and double nuts to lock to prevent vibration and loosening.

Bridge and walking mechanism in place

● When lifting the main beam to the installed track, be sure to use a lifting device that meets the load requirements and slowly put it in place;

● Install the walking trolley (driving wheel and driven wheel on the end beam of the bridge), adjust the wheel gap, and make the two sides walk smoothly and synchronously;

● Install limit blocks at both ends of the main beam to prevent the trolley from accidentally derailing.

Installation of lifting mechanism

● Hang the electric hoist or chain hoist on the hook or pulley of the trolley;

● Adjust the verticality of the hoist and the bridge to ensure that the hook is perpendicular to the bridge deck;

● Fix the cable drum or cable busbar, leaving enough room for movement to avoid dragging and wear.

Wiring of electrical control system

● Install the control box on the ground or the side of the bridge to ensure easy use by the operator;

● Connect the power supply, control circuit and grounding protection according to the electrical schematic diagram;

● Check the connectivity of safety circuits such as emergency stop button, limit switch, overload protection device, etc.

Safety inspection and debugging

Structural safety inspection

● Check the preload of all bolts to ensure that there is no looseness at key connections;

● Check the reliable function of the guide rails, limit blocks and anti-slip devices;

● Confirm that the support beams and hanging ears have no obvious deformation and cracks.

No-load test run

● First, carry out no-load start-stop, travel, lifting and lowering tests, and observe vibration, noise and electrical protection actions;

● Gradually increase the travel speed and lifting speed to verify the slow start/slow brake effect;

● Test whether the upper and lower limits are accurate, and whether the emergency stop and overload protection are sensitive.

Load test and verification

● Install qualified weights or standard test blocks, and carry out a static load test of 1.25 × rated load, and keep it for 10-15 min;

● Carry out dynamic load tests to simulate the lifting and walking actions of normal operations and test the reliability of the coordinated work of various mechanisms;

● After the test is passed, fill in the equipment acceptance report and affix the inspection certificate.

The installation of small workstation bridge cranes, from on-site survey to commissioning acceptance, to operation training and maintenance, can ensure that the equipment serves the production workshop safely, stably and efficiently. If you need a customized installation plan or professional technical support, please contact our engineer team!