Why Choose KBK Aluminum Alloy Rail Cranes

KBK aluminum alloy rail crane has outstanding performance in space utilization, equipment flexibility, and long-term durability in the field of industrial handling. Its unique material advantages and modular design have become an ideal solution for industries such as automobile manufacturing, electronic assembly, food and medicine, and clean room semiconductors. This article provides selection references for industrial customers from the perspective of aluminum alloy material characteristics, KBK system advantages, classification, and typical scenarios.

1. Lightweight design reduces the burden on the factory

The self-weight is reduced by more than 50%: The density of aluminum alloy is only 1/3 of that of steel, and the weight of the track and main beam is greatly reduced, reducing the load on the roof or supporting structure of the factory, which is especially suitable for light steel structure or old factory renovation.

Convenient installation: Only 2 people are needed to complete the installation of a single 6-meter track, saving 30% of working hours and supporting rapid production.

2. Excellent corrosion resistance, adaptable to harsh environments

Natural anti-corrosion: The surface oxide film of aluminum alloy can resist moisture, acid, and alkali vapor (such as electroplating workshop, food processing area), with a service life of up to 20 years, eliminating the need for regular coating and maintenance of steel.

Clean room adaptation: No risk of iron chips falling off, meeting the dust-free requirements of the electronic semiconductor industry (ISO 14644-1 standard).

3. Smooth operation and fast installation

Smooth operation and low noise: The aluminum rail has a smooth surface and low rolling resistance, ensuring smooth operation of the trolley, low noise, and improved operating comfort.

Easy installation and simple maintenance: Bolt connection is used, which is quick to install, and the modular design facilitates system expansion and transformation, with a low maintenance workload.

4. High strength and versatility

Aviation-grade material: 6061-T6 aluminum alloy is used, with a tensile strength of ≥310MPa, and a dynamic load covering 125 kg~2000 kg, which meets most light handling needs.

Non-magnetic: Avoid interference with precision instruments (such as medical equipment and laboratory scenes).

The core advantages of light small monorail crane

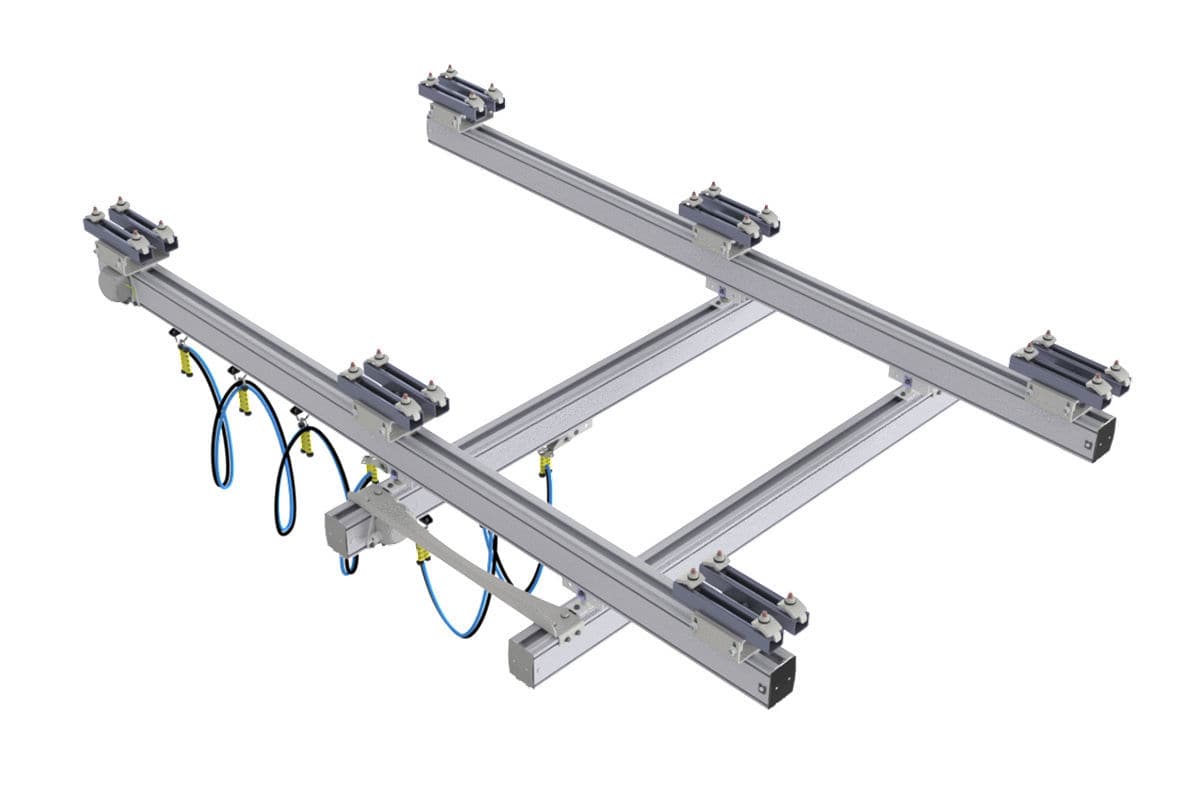

• Modular design, flexible configuration: The system consists of standardized components, which are easy to assemble, disassemble, and expand quickly to adapt to the changing needs of the production line.

• Efficient operation, energy saving, and environmental protection: The lightweight structure and precise track design reduce the running resistance, improve the handling efficiency, and reduce energy consumption.

• Strong compatibility and good scalability: It is compatible with the existing KBK system and supports the combination with rails to meet the requirements of larger spans and loads.

• Safe and reliable, long life: The structural design adopts a high safety factor, and the closed track design prevents dust from entering and extends the service life.

Classification of KBK cranes

• Single beam crane: Suitable for small span and light load station handling, simple structure, and easy operation.

• Double beam crane: Stronger carrying capacity, suitable for medium load handling tasks, usually used with electric hoists.

• Suspension system: The track is suspended on the top structure of the plant, without the need for ground tracks, maximizing the use of ground space, suitable for factories with limited space.

• Self-supporting system: comes with supporting columns, suitable for places where the suspension system cannot be installed, and is flexible to install.

• Ring track system: The track is a closed ring, suitable for continuous production lines, such as automobile assembly lines.

Typical application scenarios

1. Automobile manufacturing industry: Lightweight body parts handling, precise docking of battery packs.

2. Electronics and semiconductor industry: Dust-free handling of wafers and optical components.

3. Food and pharmaceutical industry: Aseptic filling line, corrosion-resistant clean environment.

4. Warehousing and logistics center: E-commerce package sorting, light shelf replenishment.

KBK crane redefines the boundaries of industrial handling with lightweight, corrosion resistance, and high flexibility as its core. Its modular design is not only suitable for a variety of scenarios, but also reduces costs and increases efficiency for enterprises with low maintenance costs and long life. Whether it is a precision electronics workshop or a harsh food processing environment, the aluminum alloy KBK system is a reliable choice to help enterprises move towards intelligent and green manufacturing.